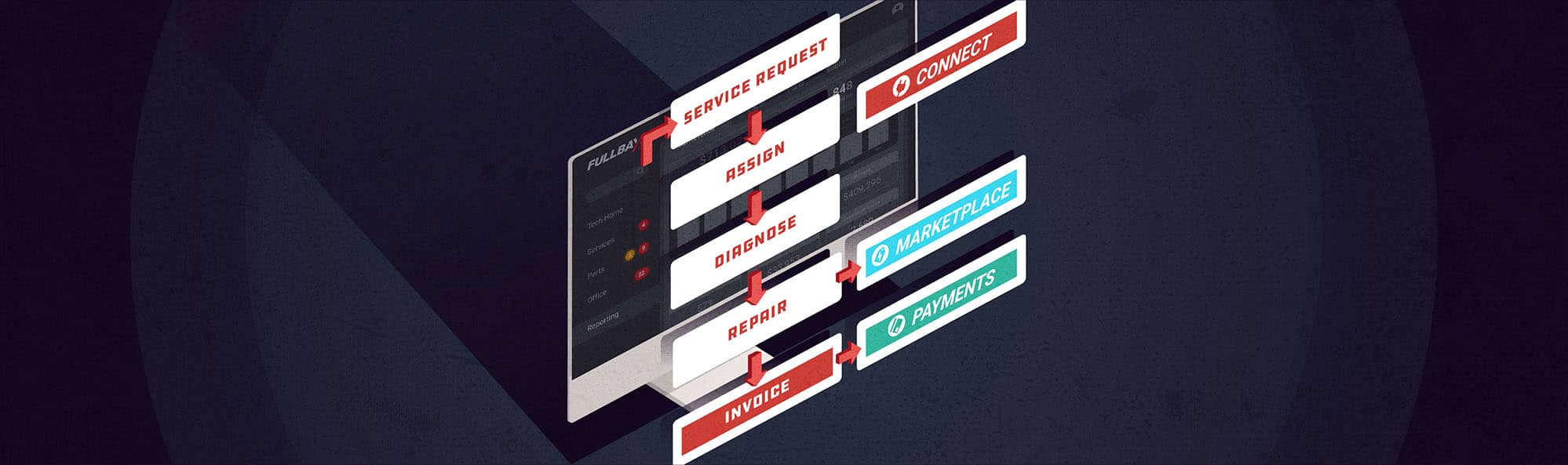

The Fullbay Workflow

If you’ve spent any amount of time on the Fullbay blog, you know we spend a lot of time talking about how our software can help your shop run more productively while improving your bottom line. We’ve highlighted how Fullbay can improve technician efficiency and streamline parts management, and today we’re going to talk about another way the app can improve your shop’s productivity and increase your ROI.

Yes, folks, it’s time to learn a bit about the Fullbay workflow and what it can do for you.

PERKS OF THE FULLBAY WORKFLOW

The workflow, in a nutshell, is a process. It’s a series of tasks, executed in a particular order, that let you stay on top of repairs and maintenance without leaving money on the table.

NO CUTTING CORNERS

The average heavy-duty repair shop faces a lot of situations where it can cut corners. When you cut corners, you end up cutting your margins and your profits. Maybe you don’t bill a part on time, or you just eyeball the clock and put down an estimate of your total hours worked. You’ve got a lot going on and you figure you’ll get to it later. Except you still have a zillion things to do, and sometimes “later” is months later.

Kirk Burchak of Coppertop Truck Repair provided real-life examples of both these issues for one of our case studies. His techs would eyeball their labor times and put down, say, two hours for a job, but those two hours weren’t entirely spent on repairs. Waiting for authorizations, ordering parts, and breaks ate into that labor time. Once he switched to Fullbay’s workflow, Kirk realized they were losing, on average, 1.5 hours of billable work per day that added up to hundreds of lost labor dollars every month. Oh, and then there was the time his shop forgot to bill a $6,000 part until six months later.

This doesn’t happen with the Fullbay workflow, which is all about covering your bases. When you complete tasks in order, and sign off on them each time, you don’t have the opportunity to push them off until later. You can’t forget to complete something because you simply can’t move on until you do it.

STAY ON TARGET

Only the people that are assigned to a job should be working on that job, right? This sounds obvious, but you’d be surprised by how many people wind up touching a job that they don’t need to. Your parts manager shouldn’t be jumping in and out of the bay to find out if this truck or that one needs this or that part. After all, you’re paying them to source parts and handle cycle counts. The more they’re stuck in the bay talking with technicians, the less time they have to focus on their actual job.

When your shop runs on Fullbay, the workflow guides everything. Your parts manager doesn’t get pinged until they need to get a part. The information is all right there in the app when they glance at it. They can order the required parts, no tracking down techs required. In short, this workflow will save you time, which is your most valuable asset. How many hours do you lose when your staff are going in and out of jobs and not keeping precise track of their hours? How many parts have you forgotten to charge for because “you’d deal with it later”?

Follow the steps and take back that time—and all those billable hours.

The Fullbay workflow leads to real financial results for shops. AAA Semi-Truck & Trailer registered a 36% increase in labor revenue once they adopted Fullbay’s workflow, as well as a 40% increase in net profit.

WHY IS THE WORKFLOW SO EFFECTIVE?

The workflow works because it leaves no room for error or going off in the wrong direction.

Let’s set the scene. You own a shop that runs on Fullbay, and a job comes in – a truck with an oil leak. The owner isn’t sure why it’s leaking oil; they just want you to take care of it. You’ll look over that job, note the complaints (in this case, an oil leak and anything else you might spot) and get a service order (SO) started.

There are between six to eight steps in the Fullbay workflow, depending on what parts you have in your shop. Here’s the order you’ll complete them in.

- Assign the job to a technician.

- Diagnose the problem(s). Sure, the vehicle in our example came in leaking oil. But the tech will need to determine the reason for the leak, as well as noting anything else that needs attention (or maybe some preventive maintenance that needs to be completed).

- Quote the parts you’ll need. Will the leaking oil be solved by a new gasket? Great. If you already have the part in your inventory, Fullbay will pull its price into the SO; if it’s not, Fullbay will notify your parts manager that they need to price out a new gasket.

- Authorize the repair. This is where you tell your customer what the issue is and what it will cost to resolve it. If you have our MOTOR integration, the cost of labor you cite will be tied to industry standard MOTOR labor times, so both you and your customer will feel secure about the estimate. This is also where you’ll indicate any other problems you may have uncovered during your diagnosis. You can get your authorization the old-fashioned way, via a phone call, or through email or with a text message containing a link to the Customer Portal.

- Order the necessary parts if you don’t have them in stock. The Fullbay Marketplace streamlines and takes the stress out of procuring parts amidst supply chain shortages. You can compare and purchase parts, as well as review ship dates and cross-references, all within the app. If you do have the parts in stock, you just mark it as “received.”

- Receive any parts you’re waiting on.

- Repair the vehicle. With parts and authorization in hand, your tech(s) can get to work on the repair. Thanks to the parts cross-reference, up-to-date labor times, wiring diagrams, and step-by-step service guides you get with the MOTOR integration, techs of all experience levels can get down to business with confidence.

- Invoice the customer. You can send an email to the customer containing an invoice, or send a text message containing a link to the Customer Portal. Don’t forget to add fees to cover things like credit card processing—that’s definitely a cost you can and should pass on to your customers. In addition, our partnership with Interstate Billing Service means your shop can settle up after a repair much faster. If your customers are also IBS members, you can bill IBS and receive payment instantly. You can also receive payment via credit card and ACH through Fullbay’s Integrated Payment options.

If all this seems like a lot, rest assured that it isn’t. Fullbay makes the above process quick and easy; setting aside the time required to receive a part and make a repair, you can get this process underway and completed within a couple minutes. It’s the absolute best-in-class workflow for a heavy-duty repair shop. Our own customers report a 20% increase in SO revenue after sticking to the Fullbay workflow for six months. And the growth doesn’t stop there; most shops see 32% growth starting at around nine months.

With that said, we understand that every business is unique. If you really don’t need to use every step, Fullbay provides the flexibility to customize the workflow to suit your needs.

And there you have it. The Fullbay workflow works—and it can work for you, too. If you’d like to see it in action, get in touch with us so we can give you a free walkthrough. We’d love to show you what we can do!