Diesel Particulate Filter (DPF) Regen and Repair

Diesel particulate filter regen is a relatively recent issue facing truck and fleet owners.

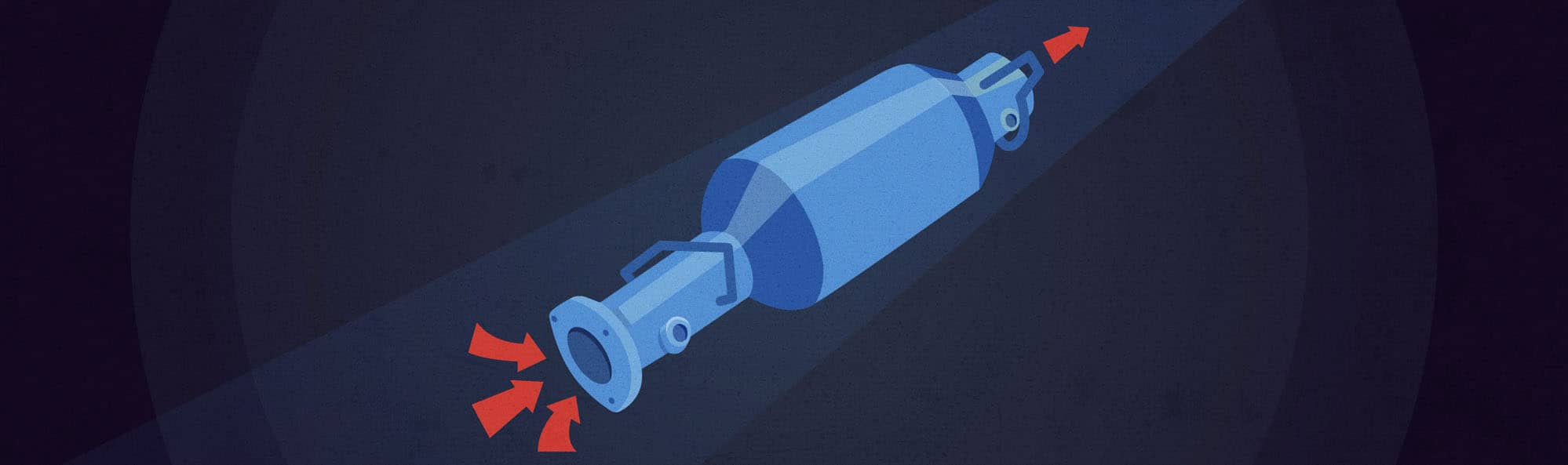

By “recent,” we mean 2007; diesel trucks from that model year and onward are “blessed” with a diesel particulate filter (DPF). These filters grab soot from your exhaust before it blows out into the environment. It’s a wall-flow filter usually made of cordierite, silicon carbide, or a ceramic monolith.

As the exhaust gasses pass through the filter, it captures somewhere between 85%-100% of diesel particulate matter (DPM). The filter removes a lot of the DPM—so much so, you could place a white handkerchief over the exhaust pipe and it would stay white.

But over time, soot builds up in the DPF filter walls. It needs to go somewhere and be cleared out. Burning the soot out of the filter is called regeneration.

DPF maintenance is relatively straightforward. A warning light usually shows up, indicating it is time to literally burn out the accumulated soot. In addition to regeneration, periodic DPF cleaning is required, too.

We’ll discuss both of these things in more detail below.

Diesel Particulate Filter (DPF) Regen

DPF regen happens when the trapped particulates heat up enough to combust and turn to ash. The built-up soot is then removed as gaseous carbon dioxide.

Regeneration may happen one of three ways: passive, active, or forced.

Passive Regeneration

Passive regeneration happens automatically. Once the exhaust temperature reaches a certain point—we like to use the example of driving at high speeds—the built-up matter in the DPF turns to ash.

No active changes in engine operation are involved. As another example, diesel trucks that frequently climb hills should have no problem passively regenerating their DPF. Under these conditions, soot burns off as fast as it is generated!

Active Regeneration

Active regeneration happens when changes in engine operation are required to get the Engine Control Module (ECM) to burn out and/or some catalyst is introduced. This is common among trucks with a lighter duty cycle, because soot accumulates while idling or going slowly through traffic.

One active regeneration method involves the ECM tweaking engine parameters to increase the exhaust temperature. The ECM then switches on an extra fuel injector that shoots fuel into the exhaust stream. This fuel reacts with a catalyst and burns the built up soot out of the DPF.

As a side note, newer engines allow for different methods of regeneration, even while “parked” or in neutral.

Forced Regeneration

If active regen requirements aren’t met or soot levels rise to a certain point, you may need to perform a forced regeneration. You’ll need a diagnostic tool for this. You’ll also want to get to work on it sooner rather than later, as continuing to operate the vehicle at this stage can ruin the DPF and cause other damage.

But even a forced regen will not work if soot levels have overwhelmed the DPF. At about 85% soot capacity and above, the DPF will need to be either removed and cleaned or replaced.

Be warned—a new filter can cost $5,000 or more.

Cleaning

You’ll need to clean the DPF every 150,000 to 300,000 miles to remove accumulated ash. This ash buildup is not necessarily related to regens, but is most often due to sulfated ash in the engine oil. You’ll also need to clean the filter if a fuel injector or turbo problem causes contamination with engine oil or non-combusted diesel. This contamination causes unacceptable back pressure.

Cleaning methods include air blasting, the use of deionized water, and a vacuum-like system. You’ll need to clean very, very carefully so as not to damage the filter, and removing particulate matter must be handled with the proper equipment and care so technicians are not exposed to its extremely fine contaminants.

Timewise, we’ve generally found that cleaning a DPF is a quick enough process—it can usually be accommodated during an oil change.

DPF and Preventive Maintenance

You guessed it: the diesel particulate filter is one more thing that must be tracked and maintained on a heavy-duty truck. Making sure the truck is on a regular preventive maintenance program will help ensure the long life of the DPF, as will regularly replacing air filters and fuel filters. While expensive for truck owners, the removal of diesel particulate matter before it blows into our breathing air certainly has its benefits, and using the correct type of oil for the engine will also help prevent unnecessary wear and the problems that can come with it.

Fortunately, Fullbay makes it easy to maintain your or your customers’ DPFs—but that’s not all. It also helps you track preventive maintenance, streamline your shop’s operations, and run a more profitable business. Schedule a free demo of our shop management software.