Heavy Truck Shop Parts Pricing

So many heavy-duty truck shops underprice their parts. A lot are not getting the profit margin they need (and may not even be covering their costs). Some picked a markup percentage long ago and just stuck with it. Others feel bad about making any profit on parts.

In today’s ecosystem, though, sticking with an older percentage or refraining from raising markup is really going to hurt your shop. We talk more about this issue below, but for now, understand that what used to work doesn’t work anymore.

Look at it another way: If you don’t make a profit on parts, you have to make it up in other areas. As we discuss in our shop profitability article, even the nuns that founded St. Joseph’s Hospital in Phoenix baked a profit into all the work the hospital did. They followed the mantra “No Margin, No Mission.”

Even a charity needs a healthy margin to keep the doors open.

That means you do, too.

If you want your shop to survive and thrive, you must make a healthy profit on your parts. Ready to sort out how you should price your parts?

Keep reading.

Heavy Truck Shop Parts Pricing and You

You’ve got to be deliberate when pricing parts—it won’t just happen in a vacuum. Sure, customers complain when parts are priced too high. But making a profit is how you survive. When hashing out how to price your heavy-duty truck parts, follow this recipe:

- Know your numbers: Add up your costs so you know how much needs to be covered.

- Do the math: Start with the profit you need and back into a parts markup percentage.

- Be reasonable: Charge a higher markup for lower-priced parts.

- Save your energy: Use shop management software that calculates markup for you so you don’t have to think about it every time.

1. Know Your Numbers

How much cost needs to be covered?

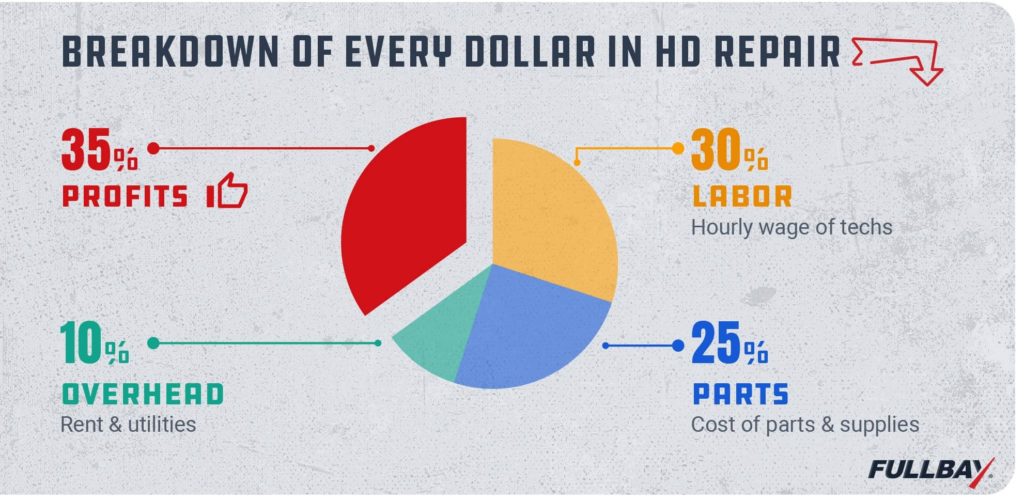

Your total cost on parts shouldn’t be any higher than 25% of sales. The chart below shows how every dollar of sales, on average, should be allocated in your shop.

Anything higher than this 30/25/10 mix eats directly into profit.

You don’t want that.

So if your cost on parts is over 25% of sales, you either need to charge more or cut your costs. There are several ways to do this; the two easiest, fastest ways to do so are negotiating prices with suppliers and keeping inventory low.

The rule of thumb is that it costs you 20% a year to carry inventory. So if you have $60,000 in inventory, it is costing you $12,000 a year to carry it. This covers the opportunity cost of the money tied up in inventory, as well as the cost of the parts room, insurance, obsolescence, and possible theft.

Cultivate a good relationship with your parts suppliers and constantly work on getting better pricing. Your shop management software should show which vendors you throw the most business to. Leverage these statistics to get better pricing; if you can look at a vendor and see how many parts you’re purchasing from them (and have purchased in the past), that data gives you more leverage to request a discount. Your software should also make parts ordering very accurate. Vendors are more likely to give you a break on pricing if your parts return rate is low!

2. Do the Math

Back into a parts markup percentage

Ideally, you’re making a 35% profit after covering labor, parts, and overhead. If your profit is below 35% after covering those, there are adjustments you can make to get there (you can learn more in our article on diesel repair shop profitability).

To put it more bluntly, to achieve 35%, your profit on parts and labor actually needs to average 45%. That’s because 10% of what you bring in goes to overhead, and after covering that 10%, you will come in at your target of 35%. If your profit on labor alone is higher than 45%, you can afford to make less profit on parts. If your profit on labor is less than 45%, you will need to make it up on parts. Heavy truck shop parts pricing done right will keep your profit where it should be.

Take care not to confuse profit and markup. If you need a 45% profit, does that mean you mark your parts up 45%?

No!

Profit and markup are not the same thing. Many shops fall into the trap of assuming they are. To achieve a 45% profit, you don’t mark your parts up 45%; you actually have to mark them up 81.6%.

If all these numbers look a little intimidating, stay with us. Resist the urge to just apply a flat markup to everything you buy—”I bought it for $100, I add on $20.” That was a popular method in the good old days when things were cheaper, but you’re leaving money on more expensive parts.

So, take a look at the table below; we’ve put it together to act as a guide in converting profit to markup. Find your desired profit. Next to it will be the markup you will need to achieve that profit.

Profit and markup are not the same thing. Heavy truck shop parts pricing involves finding the profit you need, then backing into the markup you will charge to get that profit.

By the way, if you want to build this table yourself, the formula to convert profit to markup is: Profit = Markup / (Markup + 1). Read more in our profitability article about how to reduce the cost of parts.

3. Be Reasonable

Charge a higher markup for lower-priced parts

Now you have an idea of what your markup percentage should be. Let’s say we’ve chosen 82% to get us a profit of 45% on our parts. Does this mean you charge an 82% markup across the board?

Consider the case of two parts: a $5,000 engine core and $5 wiper blades. You would get run out of town trying to charge an 82% markup on the engine core. But you could probably justify charging more than 82% on the wiper blades. Think about how much a customer will end up spending on those wiper blades elsewhere and set a cost floor for yourself. If you purchase wiper blades for $5 and a customer can’t get that wiper blade anywhere else for less than $9.10, then you can probably charge $10 for the blades and your customers won’t freak out.

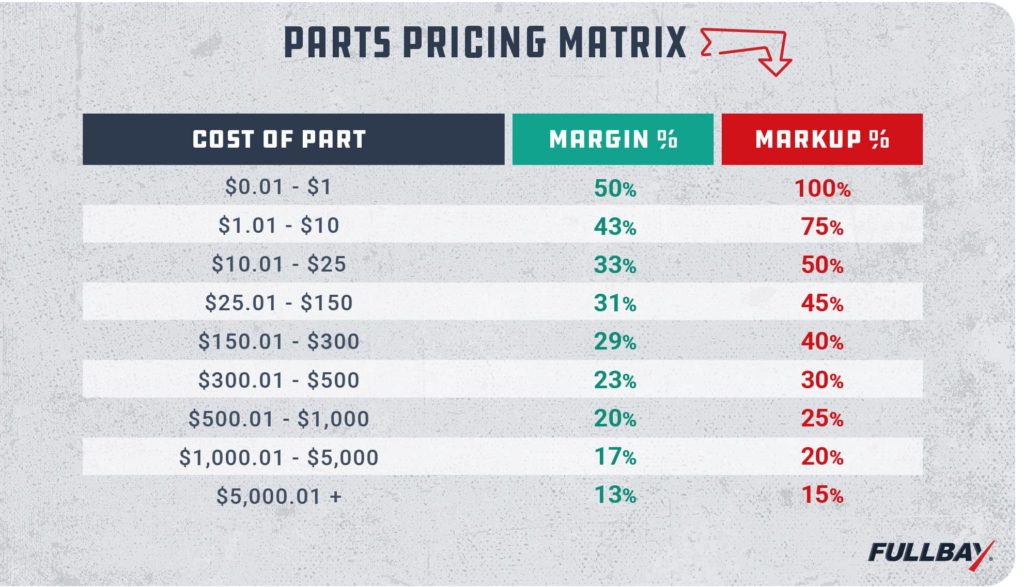

In other words, you should charge a higher markup for lower-cost parts, then gradually reduce the markup as the parts get more expensive. Heavy truck shop parts pricing should be on a graduated scale, using a parts pricing matrix—and if you’re interested in that subject, we’ve got a webinar on it right here.

Heavy truck shop parts pricing should be done on a graduated scale. Below is an example parts pricing matrix that shows a higher markup for lower-priced parts. Before looking at it, though, understand that this was built out before the pandemic and the supply chain issues that followed. These numbers, redone today, would probably look pretty different.

4. Save Your Energy

Your shop management software should calculate the markup

Don’t wait until the heat of the moment to do your parts markup. Your shop management software should do the math for you on the fly. The software should allow you to set up a graduated pricing scale or pricing matrix, so you can charge a higher markup for lower-priced parts. It should also let you modify the selling price after markup is calculated in case you need to make a final adjustment.

But you’ve likely got a lot of parts coming through your shop on a regular basis.

That’s why it’s so critical to automate parts pricing. If you wait to calculate markup every time, you’ll spend energy doing the math on markup that you could be spending more productively. Do the math once, then let your shop management software do the work for you going forward.

Here’s a quick tip from the Fullbay crew: You can set the software to “Sell Part at Highest Cost Paid.” When you do that, it automatically generates a cost floor for parts based on the highest price you’ve paid for them in the past. It’s a quick way to ensure you’re getting the profit you need.

Yeah, we like that feature a lot, too!

Start Pricing

With a little effort upfront, parts will be a steady source of profit to your shop. With the right tools, heavy truck shop parts pricing will help you achieve your profitability goals.

We built Fullbay to drive consistent, predictable profitability on parts in your shop, but that’s not all it does. It’s industry-leading shop management software that will help you run a more efficient, profitable business.

Ready to see what life with Fullbay looks like? Head over to our free demo. We can’t wait to show you what we can do!