The Good, The Bad, and the Labor Rate

All aboard, friends—we’re getting back on the labor rate train! It’s going to be a quick, easy trip with a few stops for coffee breaks and calculations.

But first, let us set the scene.

Your labor rate is what you charge your customers when they bring their vehicles to you. It is also the backbone of your technicians’ salaries. If you don’t set up a solid labor rate for your shop to start with, you’re basically setting yourself up for failure: You won’t be paying your techs enough, and on top of that, you won’t be charging customers enough for the work your techs do. From there, it’s one long topple into scrambling to pay the bills.

We’ve talked a lot about raising your labor rate—why you should and how to go about it—but we realized we haven’t talked a lot about setting it, and folks might need some help in that area. Also, we really wanted to complete our Man With No Name-themed trilogy.

So, how do you choose the correct rate and set yourself up for success?

You ask a lot of questions. You make some important decisions.

To give you a hand, we called upon the expertise of two of our favorite Men With No Names: Fullbay Co-Founder & Executive Chairman Jacob Findlay and COO Chris O’Brien.

(Editor’s Note: That joke didn’t quite land, but I’ll allow it.)

UNDERSTAND YOUR UNDERLYING COST STRUCTURE

You can’t set an effective labor rate without some idea of what your expenses will be.

“What you charge your customers has to be driven by what your underlying cost structure is,” Jacob explains. “You have to price things in a way where you will win in the transaction.”

If you’re reading that and thinking a win for the shop means a loss for the customer, think again.

Setting your labor rate isn’t just about you raking in cash. It’s about providing a fair exchange of services. You ensure your customer wins by providing quality maintenance and repairs. You ensure you win by performing, according to Jacob, “a math calculation.”

Yep. He went there. Everything—from what you pay your techs to how you break down your profit—comes down to math.

When your operation wins, your customer wins—because you’re performing high-quality work that will make vehicles safer to drive and share the roads with. If you’re not winning, then you’ll likely end up scrambling to make ends meet—which can lead to mistakes, comebacks, and vehicles you don’t want sharing the highway with your children.

In short: winning is good for everyone.

Jacob and Chris put their heads together to come up with additional, qualitative factors that go into the overall calculation:

- What work are the techs doing? Diag (higher skill), body work (lower skill), engine teardown (higher skill)? Consider charging a different rate for these specific tasks, or these specific techs. Sure, it might be easier (on paper) to charge one labor rate across the board, but in reality your techs are all bringing different things to the table. Your labor rate doesn’t need to be one and done.

- What relationship do we have with the fleet? You can charge different rates based on what you do for them. Jacob calls this “Goldilocks Pricing,” or good/better/best. Walk-in work is the highest-paid work; customers that allow you to track their PMs get the middle rate; and customers that allow you to proactively do their PMs (with a blanket pre-authorization on that work) get the “best” (or lowest) rate.

- Mobile work vs. in-shop work? If you are purely mobile, your overhead is probably lower (and as a side note, this is something to consider if you want to start a shop but don’t want all the costs associated with a brick-and-mortar location). In general, you won’t need as much labor margin to hit your overall profit target.

HOW TO SET YOUR LABOR RATE

You understand what kind of work your techs perform. You’ve got an idea of your monthly overhead. Now you can set your actual rate.

Here’s what goes into it:

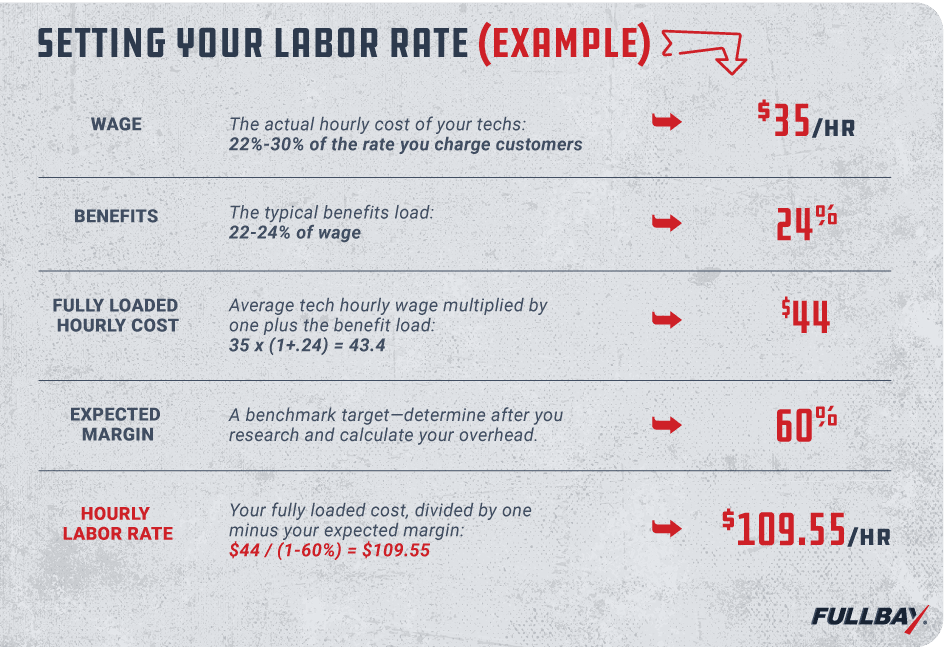

- The actual hourly cost of your techs. This is their wage. According to some unreleased data we have from the State of Heavy-Duty Repair, the hourly wage your techs receive can be anywhere from 22% to about 30% of the rate you charge customers. For this example, let’s say it’s $35/hour.

- The typical benefits load. Chris recommends plugging somewhere between 22-24%.

- Fully loaded hourly cost. This is your average tech hourly wage multiplied by one plus the benefit load. In this case, it works out to $44/hour.

- Expected margin. This is a benchmark target—something you’ll have to choose after some research and calculating your overhead. If you’re based in a city, for example, you can expect higher overhead than a rural shop. The higher your overhead, the higher your expected margin needs to be. For our example it’s 60%.

- Hourly labor rate. Your fully loaded cost, divided by one, minus your expected margin. Poof! Your hourly rate is $109.55.

And that’s it! As Jacob said, this is mostly a calculation. Once you know what you want to pay your techs by the hour—as in, their take-home pay—all you’ve got to do is tack on the math and work out the equation. If you’re uneasy about numbers, you can play around with our Shop Labor Rate Calculator.

MAKE THE MONEY BREAKDOWN CLEAR

It takes money to run a business. When you’re an employee, you may not realize just how much money.

That explains some of the aggravated reactions that can occur when a tech sees what you charge for their work vs. what they actually take home. “You’re charging $100 an hour,” a tech might say, “but I make $35 an hour, and I don’t understand why.”

As the owner, you’ve got to be able to explain that.

“You should be able to legitimately discuss the entire thing,” Jacob says. “Some owners won’t want to have that discussion, but you still need it in your back pocket.”

Every component of your labor rate should be based on fairness and value, whether it’s between the tech and the owner or the shop and the fleet. Be willing to sit down with your techs and discuss the shop’s overhead and how often insurance goes up (and as an owner, you’ve got a couple kinds of insurance—your shop is insured, and if you’re offering benefits to your people, hooboy those bennies are pricey).

HOW OFTEN SHOULD YOU CHANGE YOUR LABOR RATE?

Once upon a time, you could probably get away with an annual review of your labor rate. These days, Jacob says, it’s at least quarterly—”If not more often”–given the price and cost structure changes in the market.

“A lot of your contracts are annual,” Chris agrees, “and your contracts should be updated to reflect market conditions—like the ones we see here—so you can do an adjustment even if you’re in a contract.”

Maybe you even want to consider your labor rate on a weekly basis. This does not mean a deep dive spent over gallons of coffee with your accountant, but you should absolutely know where you are every single week. Adjust and modify to the market as necessary; anything else and you’re trying to fix things based on what you see in the rearview mirror—not what’s ahead.

RUN YOUR BUSINESS LIKE A BUSINESS

A recurring theme in the diesel industry is that a lot of owners started out as techs. They go into business for themselves for a variety of reasons, but many of them were dissatisfied in some way with their prior places of work—so once they’re in charge, they move to Opposite Land.

Chris would like would-be owners to be careful with that.

If you hated the shop you worked at before and try to treat your entire operation like a sort of course correction, you’re leaving yourself open to a lot of financial trouble. This is how you get shops that undercharge customers while overpaying their techs. Is everyone happy? Sure…for five minutes.

Then the business goes under.

(Spoiler alert: No one is happy anymore.)

Instead, Chris says, work out what you didn’t like about the prior place—but then run your business like a business. “Was it tied to culture, the way [they treated] people? Or [they didn’t] follow through on service, or the quality went down?”

If your last job grossly underpaid their technicians, then by all means up the hourly rate for your crew—but bake the appropriate factors into your equation so you can charge for their services correctly. Your techs get paid, you get paid, and your customers get good work—in other words, everyone’s winning.