Diesel Repair Shop Profit

When the Sisters of Mercy founded St. Joseph’s Hospital in Phoenix, they didn’t do it for the money. They did, however, have a mantra: No Margin, No Mission.

They knew that if they didn’t mark up the hospital services enough, the hospital would have to close its doors. There would be no money to pay overhead or to save up for big equipment purchases. In short, the hospital could not run on charity alone. They needed to manage their finances wisely.

So by following this mantra they built one of the best hospitals in the country, including the prestigious Barrow Neurological Institute.

What Nuns Can Teach a Diesel Repair Shop

In a diesel repair shop, profit boils down to a simple formula. It’s whatever’s left after covering labor, parts, and overhead costs. If there is not enough left, you need to pull up quickly before you crash and burn.

In this article, we take a high-level look at how profit should break down (and the levers that are in your control); how big the industry average repair order is; and how profitable the average repair order should be. We’ll also discuss some of the factors that will influence those levers.

Before we go further, let’s clarify that these are starter numbers. They’re benchmarks you can shoot for if you aren’t sure where your shop is at financially, or if you know things are getting out of control and you need targets to work toward as you make improvements.

Starter Diesel Repair Shop Profit Breakdown

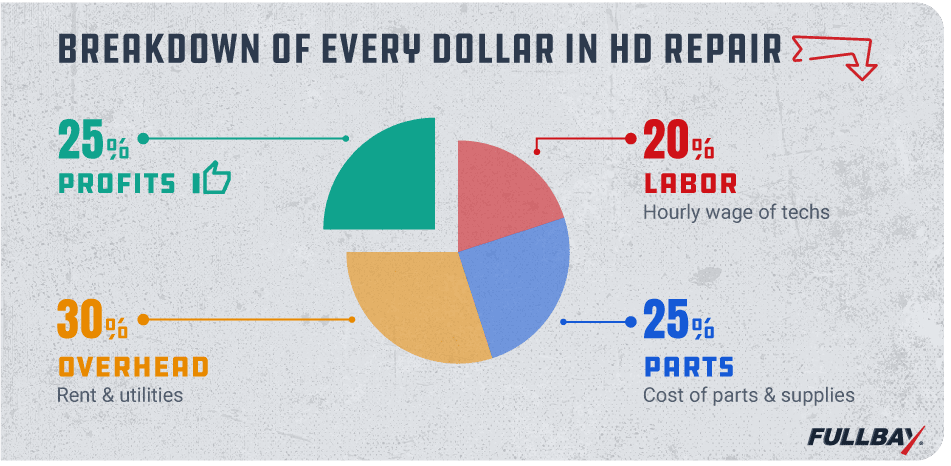

In general, if your shop is firing on all cylinders, we suggest your profit should be 25% of sales. Overhead should be 30%, labor 20%, and parts 25%.

Granted, it’s not always quite that simple. Let’s take a deeper dive.

Overhead (30%)

Overhead is ongoing business expenses that are not directly attributed to the actual repairs you do. In a shop, these expenses are generally for everything that is not labor, parts, and supplies. They include rent, utilities, office staff, business insurance, office supplies, and shop supplies. Depending on how you view your service truck, its fuel, and its maintenance (remember, some elements of overhead are judgment calls), it may fall under overhead, too.

Bear in mind that the 30% overhead described in this post usually refers to a brick-and-mortar operation, so you may see a lot of variance in this stat if you run your own numbers. Your overhead may be significantly less, for example, if you’re operating out of a truck (or even a few trucks).

Any increase to overhead comes directly out of profit.

Levers You Can Pull

- Avoid the temptation to throw bodies at problems in the shop. All this does is increase your overhead. Use tools to solve problems instead. The total cost of one $30,000 employee is about $3,000 a month. If you can find a $500/month tool that takes the place of one employee, what should you do?

- Look around for an anchor fleet. Your anchor customers are basically your retainers; they help you keep the lights on. You handle their preventive maintenance and emergency repairs for a certain amount of money each month, which goes straight to your overhead. As soon as you get a fleet account, make sure you own the PM schedule for them; then rinse and repeat—find another anchor client. Your anchor customers should absolutely be the ones who cover your overhead, and you should never have just one—because what happens if that one big fleet leaves you?

- Make sure you’re passing on the cost of shop supplies to your customers. We’ve seen shops charging 2.5% at the lowest, while the highest we’ve seen is 40%. If you’re not charging for shop supplies or you’re hanging around that 2.5%, consider boosting it to 5 or 6%.

Tip: You Don’t Need an Instant Empire

Many would-be shop owners put off profit for years because they start out believing “If you build it, they will come.” Unfortunately, this is only true in Kevin Costner movies. A huge investment into a brick-and-mortar location with all the necessary equipment and labor is a high-risk move that you don’t have to make.

You can start a diesel repair shop with exceptionally low overhead by just purchasing a good used truck with a toolbox. Yes, this will make you a mobile tech. You’ll have a truck payment, insurance, gas, and that’s it. We know of a guy who started out doing mobile oil changes; he made $20,000 a month after just three months.

Labor (20%)

When we talk about labor, we mean the hourly wage of your technicians, plus benefits and employer taxes (we’ve got a whole series on setting and raising your labor rate). It also includes the cost of a service manager, service writer, and parts manager. If your technicians are less than 100% efficient (you bill customers for every hour they work), your labor cost as a percentage of sales goes up.

Due to a variety of factors—chief among them the tech shortage—you may see this percentage go up. You are offering higher rates to lure in qualified techs, right?

Levers You Can Pull

- Let your technicians see their efficiency metric constantly. Put it on a scoreboard, in real time, and make it always visible. That way as they complete jobs throughout the day they can see how their actions directly impact their efficiency.

- As an owner, you also need to have real-time efficiency data so you can act on it and make mid-day adjustments as necessary. Funnel your shop data into a dashboard you can glance at any time you want. Don’t restrict yourself to having to be in the shop to see it. By having real-time data and acting on it, you have a direct impact on efficiency and on keeping labor at 20% of sales.

- An alternative is to pay your technicians a flat rate. They make what they bill. You can sweeten this by offering an efficiency bonus: if they meet specific numbers, they make some extra money.

- Be available when the equipment is down. That doesn’t just happen between the hours of 9-5. It may mean being available overnight, on weekends, and during holidays. This lever is easier to pull if you have a mobile repair truck (or if your entire shop is mobile). Running a mobile operation also allows you to collect service fees, set a windshield time rate, after-hour fees, and the like.

Parts (25%)

The cost of parts should be no more than 25% of sales. Your parts manager’s job is not only getting parts priced and to technicians quickly, but getting good deals on parts, whether they’re buying them from your local vendors or the Fullbay Marketplace.

Levers You Can Pull

- The parts manager has a direct impact on shop profitability by working to keep the cost of parts at or below 25% of sales. He needs to have this metric constantly visible in front of him on a scoreboard, in real-time, so he can see how his actions impact it.

- Give your parts manager the tools to negotiate with parts vendors. Let him see the full pricing history of all his parts. Let him run reports showing the volume he has with each vendor, so when the Freightliner account manager comes by with free pens the parts manager can push him for better pricing.

- Use a velocity report to make sure you’re only stocking the parts you’re actually selling. Don’t just trust your gut feeling that you may be selling a lot; only parts that you turn over quickly (at least weekly; ideally multiple times per week) belong in your parts room. You can pull a velocity report from Fullbay to see exactly what kind of parts—and how much—you’re selling, and can make an informed decision on what to keep in stock.

- If you don’t use a markup scale for inventory parts, then regularly evaluate what each part is priced at versus what it costs you. Use a shop management system that lets you easily see purchase history, find which suppliers are giving you the best pricing, and set them as the preferred vendor so you automatically order from them when you replenish stock. Leverage the preferred vendor status to get better pricing from the supplier. (Fullbay can do all this, by the way, but if you’d like to experiment give our Parts Markup Tool a try.)

- Encourage your technicians to fabricate or fix parts where appropriate. It will probably end up costing the customer less money, and you are able to charge labor hours where otherwise you’d be selling a low-margin part. That means more of the customer’s repair budget is staying at your shop, versus going to a parts vendor.

- Jump on a manufacturer’s program—for example, filters—to buy them for lower rates (which you will then mark up).

How Else Can I Impact This?

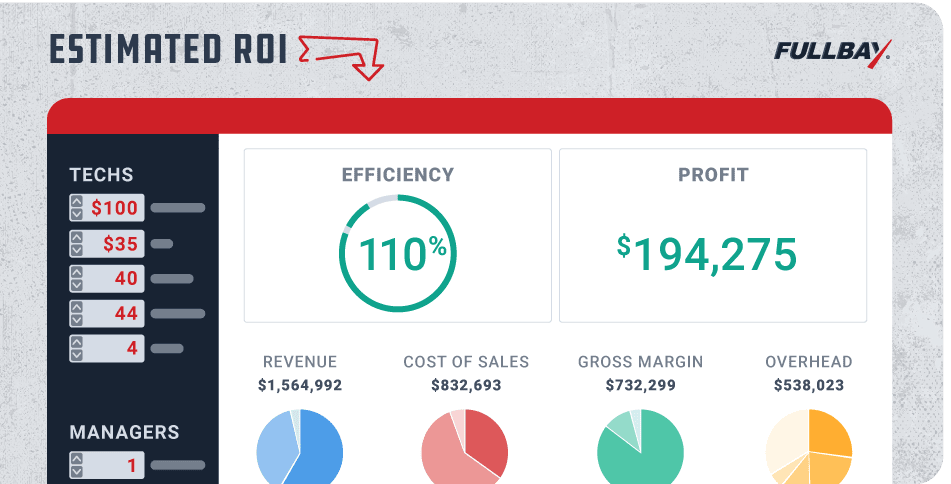

Wouldn’t it be cool if you could just plug in some numbers and see what percentages turn out? Yeah, we feel you. That’s why we built the Diesel Repair Shop ROI Calculator.

With the Fullbay ROI calculator, you can adjust numbers to see how it will affect your shop’s revenue.

You’ll start out by answering a few questions about your shop—including how many techs you have, what your labor rate is, and your average parts markup. Once you fill that out, you’ll land in the calculator, which allows you to change up the numbers and ensuing percentages.

It’s a very cool tool. So go ahead—finish reading this article and then start experimenting with numbers!

Diesel Repair Shop Profit on a Typical Job

So, what would the shop profit look like on a typical job?

The most common work order in the heavy-duty repair industry comes in at about $800. Assuming the job takes 5 hours and you charge $90/hour, you would make $450 in labor (5 hours x $90/hour). In addition, assume that you charge 8% of labor for shop supplies so you’ll make $36 in shop supplies ($450 labor x .08) and you charge $314 in parts.

Now let’s apply our percentages for labor, parts, and overhead from above to this $800 repair order. If you are able to keep your costs in line with the percentages from above, then your overhead cost would be $240 ($800 x 0.3), labor cost would be $160 ($800 x 0.2), and parts cost would be $200 ($800 x 0.25) for a total cost of $600. This would leave you with a profit of $200 ($800 – $600) or 25% profit margin on the job.

Anything outside firing on all cylinders will directly impact what you make on the job, or if you make anything at all. That means your profit evaporates as efficiency drops under 100%, your parts manager isn’t able to keep costs at 25% or below, or if your overhead creeps over 30%.

These costs can start to add up and make a big impact on what you make in your shop. You might not think that it is a big deal if you have a 25% profit margin or a 20% profit margin during the year, but if your shops make $200,000 per year that 5% difference is $10,000 ($200,000 x 0.05). I don’t know about you, but I could always use an extra $10,000.

Keep the Market in Mind

We’ve provided some high-level ideas here, but take a look at the market before committing to any changes. A common “fix” among owners is to add $5 to their labor rates. We get it; it’s easy, and that extra $5 can add up fast. But the reality of the situation is the market you’re in might not allow you to do that. If you’re already at top of market in terms of your labor rate, asking for more might not help you grow at all.

If you want to boost your profit now but aren’t sure what the market will bear, look at spreading out your increases. Add $5 to your labor if the market will take it. Add more to your parts margin. If you’re not charging for shop supplies, charging 5% can help you net immediate additional income.

We recommend giving our Diesel Shop ROI Calculator a try. Plug in different numbers and see how your revenue will go up and down. It’s an excellent way to get an idea of what your profit could be before actually committing to a numbers change.

Keep Working At It

Boosting your shop’s revenue is likely not going to happen overnight. Be at peace with that. Real change comes when you look at your operation and your numbers and make a commitment to getting closer to the benchmarks we’ve discussed.

You can do that by beginning to do these simple things:

- Reduce your overhead by putting the right tools in place

- Pull the levers in your control to increase efficiency

- Where possible, decrease the cost of parts

Your reward is peace of mind and a healthy profit.

If your shop management software doesn’t give you the levers you need to make your shop profitable, it might make sense to request a demo of Fullbay. We can discuss your shop and see if the tools we’ve built will work for you.