What You Need to Know About Becoming a Diesel Mechanic

Are you good with your hands and enjoy a challenge? Do you fantasize about pulling apart a HEMI and putting it back together again? Do you read Fullbay’s blog and think, This is for me?

(Editor’s note: Don’t flatter yourself, Suz.)

Maybe you should look into becoming a heavy-duty technician.

We don’t just say that because we love techs and all things diesel. The fact is, the diesel industry is growing, and it’s expected to continue expanding for the foreseeable future. What’s more, working on semis and other heavy machinery is a specialty area that not just anyone can do.

This translates to good money and job security, if you’re into that.

Would you like to know more?

There’s more than one way to become a diesel mechanic. You can start out the old-fashioned way, starting as a junior tech at a shop and working your way up the ladder. You can also head to school for certifications or even a degree.

Whichever path you choose, make a plan. First, make sure diesel tech is the right career for you. Then map out how you’ll get the skills and knowledge you need, and where you’ll look for a job.

To give you a hand with that, we sat down with Aaron Picozzi, President at American Diesel Training Centers. Aaron got his start as a diesel technician, and he’s familiar with both the realities of the modern diesel industry and the type of education you need to move up in it.

He had all sorts of wisdom for us, so grab a beverage, kick back, and read on!

Should You Become a Diesel Mechanic?

First things first: you’ve got to figure out if this is a passing fancy.

“Diesel mechanic is a great job for folks who don’t mind getting a little dirty and problem-solving,” Aaron says. “Can you identify a problem, assess it, and make an attempt to repair it? This is a great field for you.”

He also points out that this is a particularly good time to jump into the industry, especially for young people. We’ve talked at length about the tech shortage (to say nothing of the driver shortage!); one of the driving forces behind that shortage is the fact that older techs are retiring and there simply aren’t enough young ones to fill their shoes.

“But the industry isn’t going anywhere,” Aaron adds, pointing out that diesel kept trucking along (pardon the pun) throughout the pandemic. Techs were considered essential workers and kept their jobs even as other industries laid off vast swaths of workers.

Starting out as a diesel tech also lets you springboard into other jobs within the industry: sales, parts, shop ownership, and more—those doors open up to you once you’ve got some experience under your belt.

Flexibility and Advancement

In general, there are opportunities for advancement and raises as a diesel tech, including the option of opening your own shop and earning a shop owner’s salary. Heavy-duty mechanics’ stress tends to be average. You’ll be expected to perform at a certain level to earn your wage, and there’s always a deadline for keeping customers happy. However, to what degree those issues affect stress levels differs from shop to shop.

Often, heavy-duty techs are required to work past regular business hours and on weekends. Sometimes it’s to meet deadlines, and sometimes it’s to accommodate customers’ schedules. That’s a negative factor if you like your evenings and weekends free. However, it can be a plus if you prefer coming in later in the morning or occasionally having a day off during the week as compensation.

If you’re fine with those issues, you’ll also want to consider:

What do diesel mechanics do?

Brace yourself: a heavy-duty tech’s day is spent working on big trucks and heavy machinery. Their many duties include troubleshooting performance problems, tearing apart and rebuilding engines, rotating tires, and doing oil changes and other preventive maintenance. And that’s just the beginning. The industry is becoming increasingly more high-tech, and that means you’ll be working with computers, diagnosing issues on electric vehicles, and more.

Sometimes you’ll do all that work in the shop—but the mobile tech revolution continues, so that’s an option for you, too! These lone wolves take their expertise directly to their clients. Sometimes that means doing PMs in a customer’s fleet yard, and sometimes it means meeting the customer at the scene of a roadside breakdown. Either way, it’s a convenience for the customer and it adds another dimension to the job.

Do I need licensing to be a heavy-duty technician?

There are no state or federal laws that say you have to have formal training or be licensed or certified to be a heavy-duty mechanic. Most often, the licensing or certifications you need will be dictated by who hires you.

Some employers require nothing more than a high school diploma. Others may want an associate’s degree or at least a certification in diesel mechanics and maintenance. Additionally, many look for techs with an ASE certification. Credentials from the National Institute of Automotive Service Excellence prove you have top-level experience and skills.

We do recommend you get your Commercial Driver’s License (CDL). Even if you don’t plan to switch between wrenching and driving, you’ll need to be able to fire up and maneuver heavy equipment to get it in and out of the bays!

Are diesel mechanics in high demand?

Um, yes.

Like we said above, the trucking industry kept on rolling throughout a pandemic that sliced through other fields. Construction and heavy equipment industries are booming, too. Those factors alone mean an increasing need for skilled diesel mechanics.

According to the Bureau of Labor Statistics, there were 281,300 heavy-duty techs working in 2019. In addition, the BLS projects that number to grow to 290,800 by 2029. Remember, that’s the projected number. The industry will actually need more techs than that—but then, you already knew there was a shortage. This is largely due to older techs retiring at higher rates than younger techs can replace them.

If you still need convincing, check out Indeed.com’s hiring ads for diesel techs—and remember, these job ads aren’t necessarily a 1:1 ratio. If a shop owner is hiring five mechanics, they’re not going to post five ads. They’ll post one ad and see what they get.

“If you want to be a technician, the world is your oyster right now,” Aaron says.

How Much Money Does a Diesel Mechanic Make?

That’s cool, Fullbay, you may be saying, but how much coffee can I buy with my salary?

(Editor’s note: *facepalm*)

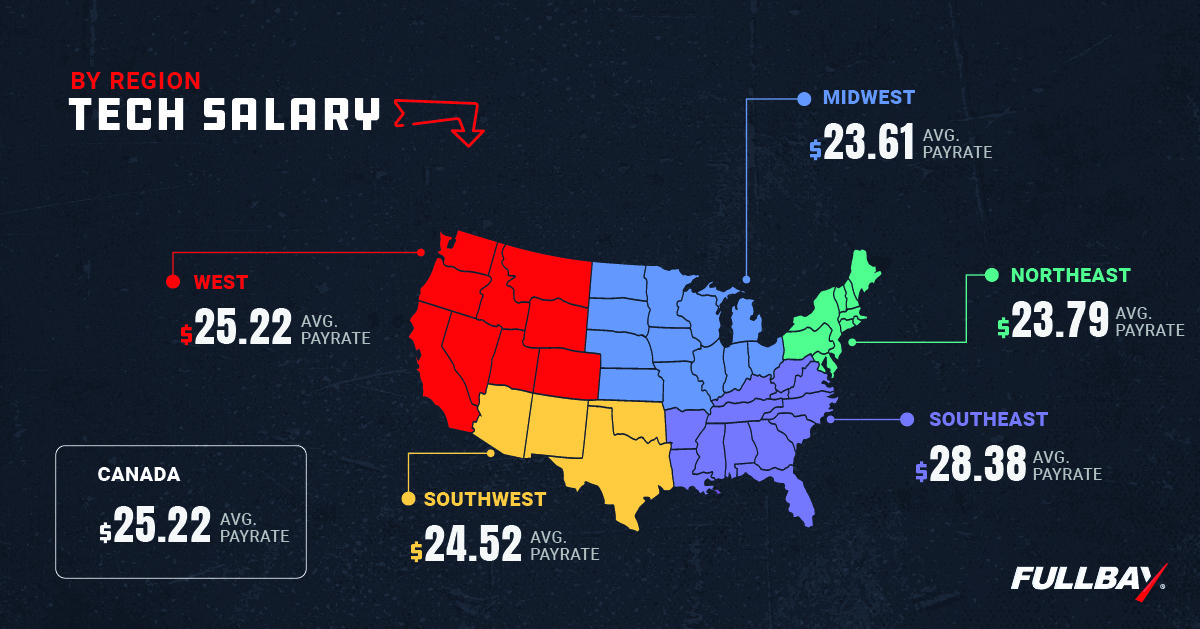

ZipRecruiter tells us the average salary for a heavy-duty diesel tech is right around $52,000. You’ll encounter variations based on your experience level and your region. We’ve looked extensively into our own data, and come up with average wages based on region below:

These are the average payrates by region that are seen across the United States and Canada.

In addition to location affecting your income, the individual shop you work for has everything to do with how much you make. Some shops pay hourly, the median hourly wage being $22.76. Hourly pay can be better than salary in some cases, such as when you work overtime. Plus, more shops are paying their hourly techs bonuses on top of their hourly wage when they perform above 100 percent efficiency.

How Long Does It Take To Become a Diesel Mechanic?

A dedicated junior tech can generally graduate to handling most PM work in under a year. After that, Aaron says, “It really depends on your level of proficiency and desire to learn.” Remember—you never stop learning on this job!

“Being a master technician is a lifetime of work,” Aaron says, cautioning that everyone is different. But you can generally figure that within three to five years you will be able to handle all kinds of repairs and maintenance, along with out-of-the-box problems.

Do I Need to Go Back to School?

If you’re already considering shipping yourself off for a two-year degree, hold the phone—we’ve got more advice. When young people approach Aaron asking how to break into the diesel tech industry, he provides an answer that often surprises them. “I tell them to go to their local shop, and tell them, and see what happens.”

Wait, what?

“Go to your local shop, tell them that, and ask if you can start,” he emphasizes. “As you grow in the industry, there is OEM-specific training you can get.”

Formal training is very important, he adds, and there are some excellent schools for you to choose from, but make sure you have a game plan going in. What is your goal? Will you leave with a great job, or minimal to no debt? What result are you hoping for from your diesel education?

No matter what type of education you pursue—shop-based or school—Aaron wants to emphasize that you never stop learning. “You can’t surge experience,” he remarks. This industry is always changing; you’ll be working on new types of technology, new equipment models, and so on.

With that said, there are some excellent schools out there with top-notch diesel programs. Here are a few:

If you do decide you want to head to school, look for the following qualifications at any campus:

- Accreditation: Look for a school with credentials from nationally-recognized organizations like the National Automotive Technicians Education Foundation.

- Real-world training: The best programs have on-site garages and provide 30 hours or more of hands-on training each week.

- Facility and equipment: If it’s possible to tour prospective schools, do so. See with your own eyes the amount and type of equipment you’ll be learning on and the environment you’ll be learning in.

- Certification: You’ll want to attend a program that turns out grads who have no problem getting ASE certified. Also, if you want to graduate with a specialty certificate, look for schools that offer the certification(s) you’re interested in.

- Graduation and on-time completion rate: Look for a program with a high percentage of students who graduate from it and who graduate on time.

- Recommendations: Find testimonials from past students, if you can, but also talk to techs, managers, and repair shop owners to see if they recommend specific schools or programs.

- Job placement and assistance: Look for programs with a good job-placement track record. Some schools boast 80 to 100 percent job placement within three to six months of graduation.

Whichever path you take, you should always put continuing education on your priority list. The industry is constantly changing as new technology arrives, and you’ll want to make sure you keep up with those changes.

And while we talk a lot about trucks here at Fullbay, there’s a whole world of other diesel specialties you can check out. Aircraft, marine engines, school and transit bus engines, electrical systems, or construction or farm equipment are all on the table. You can also get certified to work on forestry equipment or specific brands such as John Deere or Kenworth.

Pro Tip: The more you learn, the more value you offer employers, and the more your earning potential will go up.

Got Diesel?

Aaron may not be actively wrenching every day, but there are still two huge draws to becoming a diesel mechanic. The first is that the knowledge you obtain as a diesel tech will always be yours—no matter what field you end up in, or where your career takes you, you will have those skills to fall back on if you need to.

The other, he says, is that being a diesel tech makes you part of a global ecosystem. A tech is one link in the chain that keeps necessary supplies moving all over the country and the world. The truck you fix might deliver life-saving medicine to someone. That’s pretty important!

Ultimately, no matter where you end up in the diesel world, the work you do will make a difference—not only in your life, but potentially in the lives of millions of people you may never meet.