Regenerative Braking

Trucks that fall into the heavier classifications serve society in a variety of ways, from delivering vital cargo across long distances to hauling garbage and other refuse away from populated areas. Technology hasn’t progressed very much for machinery that is such a vital part of modern life. However, electric vehicle features such as cleaner operation and regenerative braking are now being used in heavy-duty truck design. The braking feature alone makes the trucks of the future more efficient and safer to operate.

Current Braking Systems

Semi-trucks are much larger than vehicles in smaller classes, specifically passenger vehicles. The size difference means they don’t handle the same, like when stopping. For one thing, the larger size of the semi gives it more momentum than a car, even when they’re going the same speed. That results in the need for a different type of brake system.

Light and medium vehicles typically have hydraulic brakes. Heavy-duty trucks rely on air brakes. Hydraulic brakes basically work instantly. When the driver presses the brake pedal, it sends brake fluid to pistons on the wheels and engages brake pads that slow the car down, all within a split second. While this system is effective for smaller vehicles, it doesn’t work well on a larger scale for semis with a detachable trailer. That’s why they use air brakes.

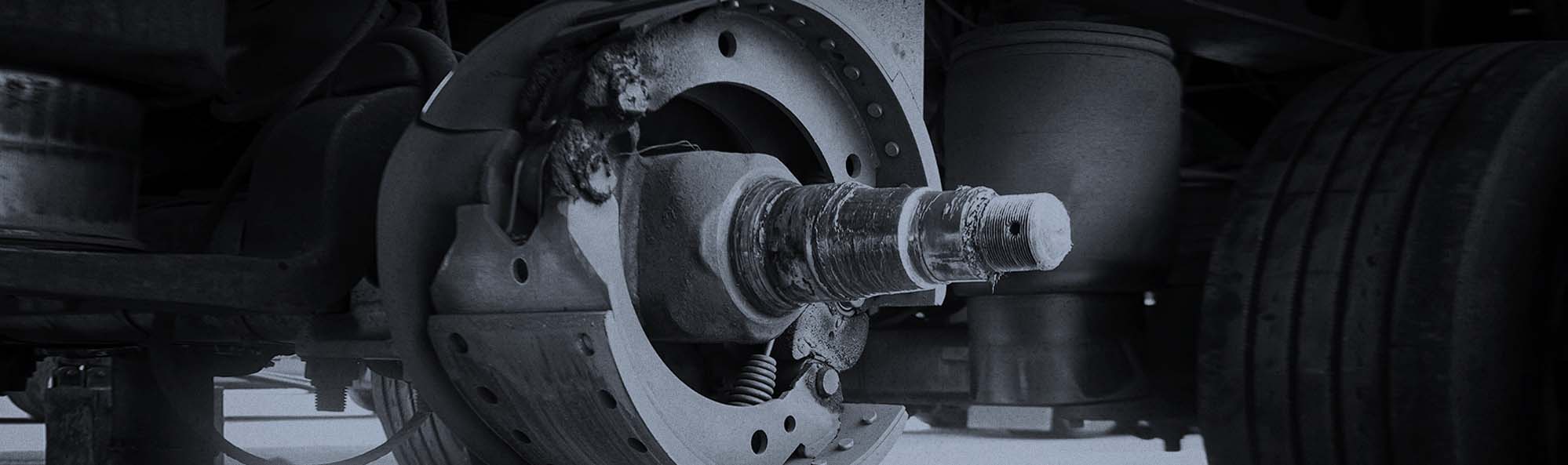

In an air brake system, pressing the brake starts a similar chain reaction to hydraulic brakes, but there are more steps. First, stored air moves through lines into the brake chamber. The forced air presses a pushrod against a slack adjuster and causes the camshaft to turn. That action makes the S-Cam twist, forcing brake linings against the brake drum. It’s not until that final step that the truck starts to slow down. Though there are several steps, it all happens within about 1 second’s time. It’s a short delay called brake fade. The process is still fairly quick, but brake fade’s minuscule lag means drivers have to be alert at all times and time their braking differently than when they’re driving smaller vehicles.

The Importance of Air Brakes for Today’s Semis

There’s one vital difference between hydraulic and air brake systems. If the brake fluid leaks out of a hydraulic system, the brakes can’t engage, and they fail. That’s a scary enough notion for a car, but a devastating and tragic one where a heavy-duty truck is concerned. On the other hand, air brake systems are far more reliable. Even if some or most of the air leaks out, the default system engages, and the truck still brakes. That’s because there’s a massive spring inside the brake chamber, held back by the steady airflow. When air in the system drops to a level that isn’t sufficient to keep the spring in place, it uncoils to engage the brakes and complete the process.

Benefits of Regenerative Braking

Now let’s take a look at how electric battery-powered vehicles brake. Instead of traditional compression braking, they use regenerative braking to stop. The way it works is to reduce pressure on the accelerator. You gradually let up on the pedal to slow the vehicle down, eliminating pressure to come to a full stop.

Regenerative braking has many benefits. First, it turns the vehicle’s kinetic energy—the energy produced by motion—into a form that can be stored or used right away. For electric vehicles, the logical use is for the motor to catch the energy, recharging the battery for driving. That is exactly what they do.

Helping keep the battery charged extends how far the vehicle can go before needing a recharge, and that’s just one benefit of regenerative braking. Other pluses include conserving energy, increasing braking efficiency, and reducing wear on the brakes. In fact, regenerative braking is so easy on brake systems they’ll possibly last longer than the vehicle.

Regenerative Braking: the Future of Semis

Electric cars already use regenerative braking, and the technology is now being used in larger class vehicles. Tesla leads the way with a Class 8 semi that the company claims charges quickly, has about a 500-mile range, and employs regenerative braking. Because of safety standards, semis will still likely need to have air brakes, but only as an backup system. Of course, the best-case scenario is that drivers would never need to use the air brakes. That means braking systems would last pretty much forever, saving time, money, and maybe even lives. It looks like the future has already arrived.