Ins and Outs of Inventory

Quick! A customer needs a part. Do you have it in your inventory?

If you had to pause and think about it, that’s OK. We’re not judging you.

If you’re like most shops, you carry some parts in your inventory. Usually these are the things you put to use on a regular basis: bolts, cables, and so on. But you probably also carry smaller quantities of some larger objects, like axles and the occasional transmission.

But do you really know what’s in your inventory?

Have you ever sold a part to a customer and gone to fetch it, only to realize you don’t actually have it? Or worse, have you ever realized you paid a vendor for parts that you forgot to enter into your inventory?

(That’s what we call “bleeding money.”)

But not to worry. There’s a lot you can do to get your inventory in shape so you know exactly what you’ve got at any given time. Read on to learn more!

PROTECT YOUR SHOP WITH PURCHASE ORDERS

A purchase order, or “PO,” comes to you from the vendor you purchase your part(s) from. It’s full of critical details – we’re talking the vendor’s identifying item number, the parts you want, line descriptions, and of course the prices.

You can learn more about them here, but in a nutshell, a PO helps you make sure the contents on the vendor’s bill matches what was ordered. You’d be surprised how often parts don’t entirely match up – and this is rarely malicious, by the way; sometimes a parts driver grabs the wrong box, or a vendor makes an honest mistake. A PO catches those mistakes before they can become costly.

RECONCILE YOUR INVENTORY

The most basic way to make sure that your records match your stock room is to reconcile your inventory.

- Count all the parts on your stockroom shelves. Make sure everything is in there – do a quick scan of the bays to ensure nothing is left behind. Now, if you’re like other shops, you’ve got a parts room (or possibly a parts corner, or parts bin, depending on how large you are). You should be visiting that parts room at least semi-frequently to make sure that your actual inventory matches what you have on your spreadsheets (or in your head, if that’s how you roll).

- Compare the results of that count to your records.

- Determine whether there are differences between the two.

- Adjust your records to reflect the physical count.

But Fullbay, you’re saying, I am so careful with my parts! Why would #3 even be a problem?

Because you are human, and we assume your techs are human. Humans make mistakes. Someone could have misread a serial number, or ordered the wrong part, or put something where it didn’t belong. Paperwork might be late or not in the system yet. You might have ordered a part and forgotten to invoice for it. And so on and so forth.

Reconciling your inventory basically keeps you updated on what you have in stock and what you need to get. It’s not perfect, and it can take time to do, but we recommend reconciling your inventory at least once a month.

TRY THE THREE-WAY MATCH

You can cut down on some of the potential user errors we described above by sharpening up your parts receiving process. We’re borrowing the term “three-way match” from the accounting world, but it’s basically fancy talk for making absolutely sure that what you ordered was delivered, and that it matches the invoice you’ll have to pay.

When something arrives, make sure the following three things match:

- Your purchase order

- The vendor’s invoice

- The parts themselves

Here’s how it works: The vendor shows up with the parts (or you run and get them). The vendor will hand you the parts and an invoice. Take the parts and compare them to the invoice. Make sure the invoice matches the parts they gave you. Check descriptions. Make sure part numbers and quantities match exactly.

Next, compare the invoice with your purchase order. Once again, read the descriptions and make sure quantities and dollar amounts match. If anything is off, investigate. If everything looks good to go, you can confidently pay that bill when it comes due because you know two things:

- You actually received the parts, and

- The customer was invoiced for them

Managing your parts receiving this way can do a lot to take the pressure off your reconciling system. And if you know you’ve got the right parts on hand or ready to go for a customer, well, that’s more revenue for you.

USE FULLBAY FOR CYCLE COUNTING

What do the tactics above have in common?

Paper.

OK, they also take time and brainpower. They usually involve you, a pen and some paper, your receipts and work orders, and spreadsheets. Potentially lots of spreadsheets with ten tabs or more.

You – and your parts manager, and your techs – have better things to do.

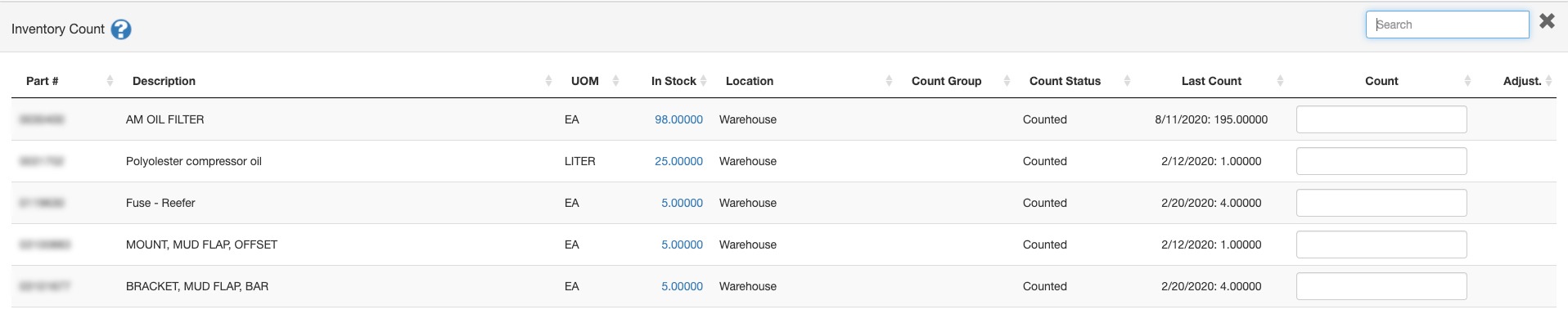

We’d like to introduce you to Fullbay’s cycle counting feature, which helps you ensure that you actually have the inventory you think you do. All that time you spent figuring out who bought what and where that part is and why it’s not showing up reverts to you. That’s because everything is accounted for from the moment you order a part from a vendor.

When you order a part, Fullbay will generate a purchase order and show you if the part is in your inventory or in transit. Even if you forget that you ordered the part (it happens!), Fullbay will have a record of you ordering it. When it arrives, you’ll click “received,” and it will be added to your inventory and the purchase order listed as fulfilled – automatically. No spreadsheets, no wandering through your parts room in search of this bolt or that nut.

Fullbay takes parts management a step further by tracking every part you sell and/or use in repairs. Remember our advice above about the three-way inventory? Fullbay takes a lot of the work out of that task by tracking what parts you have and sell into the following categories:

- Fast-moving parts: Items you should inventory daily.

- Medium-moving parts: Items you should inventory weekly or monthly.

- Slow-moving parts: Items you should inventory once or twice a year.

This feature helps you see what parts sell fastest – and therefore need to be replenished more readily – and which don’t sell much at all. You should still perform a visual check of your parts to make sure what you have matches up with what’s in Fullbay, but if you know that a particular part is slow-moving, you probably don’t need to look at it every week or even every month.

WHAT ELSE CAN FULLBAY DO FOR YOU?

Are you sold on using Fullbay’s cycle counts to help you manage your inventory? We like it, too, and we’re happy to say that it’s just scratching the surface of what Fullbay can do to help you run a more efficient and productive shop…and save you time in the process.

If you’re ready to get more done and bid farewell to spreadsheets, give us a call. We’d love to walk you through our free demo!