Essential Tools YOU Need for Your Heavy Duty Shop

Starting a diesel repair shop means having the right heavy-duty tools. After all, you can’t do the job without the right tools!

The best advice we can offer you is to resist buying every last thing you think you might need. Really. We know: it’s tempting. But one of the keys to heavy-duty success is to take it slow, start out with the essentials, and keep building your toolbox over time.

Build Your Own Toolbox

Lots of techs come up through school programs, so let’s start there. Most diesel tech programs have a list of heavy-duty tools students need, and that list grows longer as you advance through the courses. The good news is that you’ll complete your schooling with the beginnings of a useful toolbox.

A sample list of equipment diesel tech freshmen must have includes:

- 1/4-inch square drive socket set, including 6-point sockets, deep and shallow sockets, a reversible ratchet, and extensions

- 3/8-inch square drive socket set, including the same accessories listed above as well as a universal joint

- 1/2-inch square drive socket set, including the accessories listed above plus a flex handle

- Brakes and suspension tools like torque wrenches, spring tools, flare kits, a tire gauge, and a narrow brake spoon

- Welding and preventive maintenance tools, such as files, a welding kit, spark lighter, and torch tip cleaner

- Fuel and electrical systems tools including spark plug sockets (when you are not working on diesel), round feeler gauges, jumper wire, electrical tape, and resin solder

What’s more, you’ll also need to fill an extensive list of nearly 40 miscellaneous tools, including:

- Combination and Allen wrenches

- Punch and chisel set

- Vise grips

- Diagonal pliers

- Drill bits

- Measuring tape

- Blow gun (with a rubber tip)

- Phillips screwdrivers

- Slip lock pliers

- Toolbox

- Shop uniform

Keep in mind that lists can vary between instructors, programs, and schools, so be sure to follow the equipment list that applies to your particular course.

So, you’re done, right?

Nope.

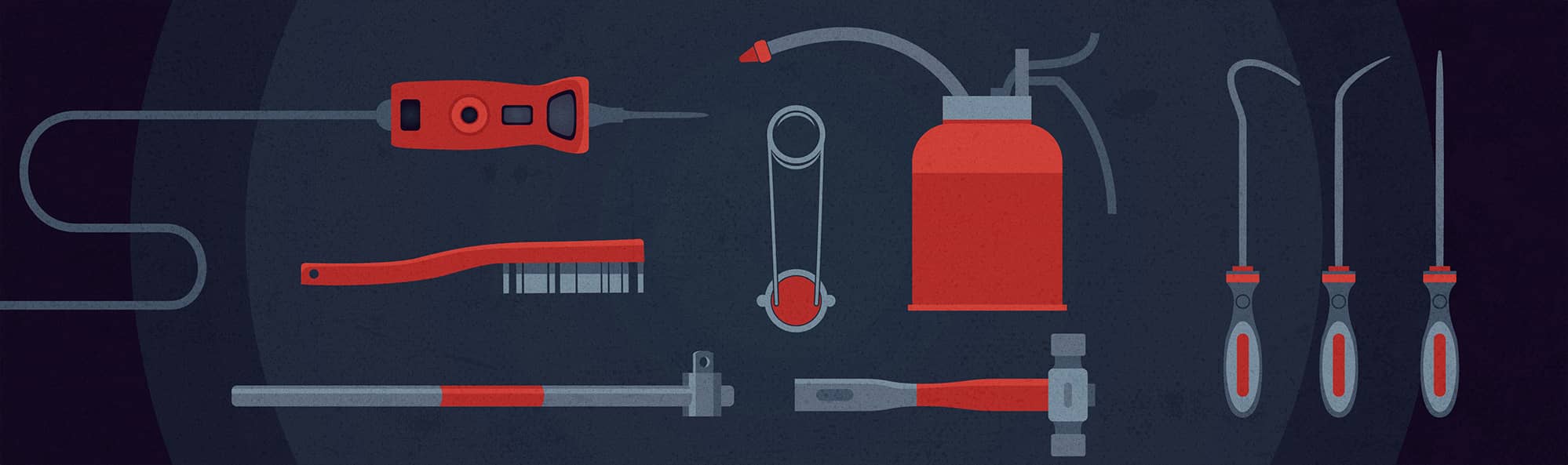

After amassing all those tools for your freshman course, don’t be surprised when the instructor hands you a whole new list for your senior course. You’ll need to still have everything from your freshman class, but will also need close to 30 more items including (but not limited to):

- screw extractors

- flexible air hose

- hand wire brush

- bearing race punch

- drive breaker bar

- grease gun

- long picks set

- creeper

- pump oil can

- dead blow and ball peen hammers

Additionally, on the senior equipment list are ear protection gear like ear muffs or plugs, for instance, as well as a few non-tool items like a calculator, flashlight, and Wite-Out.

The collection of truck tools you need for school can serve as a useful starter kit once you have your certification and are ready to work in a shop. Better yet, you can build on that existing kit as you go rather than buying a brand-new “complete” tool kit. Even if you buy a kit, chances are you will need to add to it anyway.

10 Tools to Own

Every diesel tech has their own favorite truck tools, and if you compare 20 toolboxes, you’ll find vast differences between them. Still, there are always going to be some tools they all have in common.

If you were to ask some seasoned techs what they have in their toolbox, they’ll probably advise you to get some of the following:

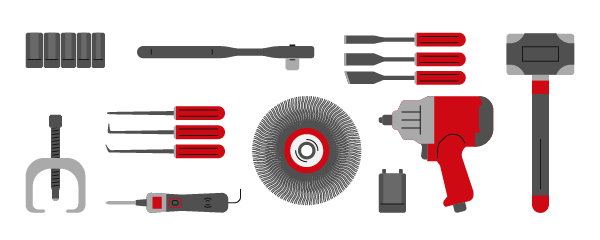

- High-quality sockets: Short-wall, deep-wall, 12 and 6-point, impact, metric and standard, Allen and hex.

- Ratchets and accessories: Ratchets (naturally), extensions, swivels, torque wrenches

- Gasket scrapers: All shapes and sizes as well as ones you can insert razor blades into

- Hammers: brass dead blow, light (5-pound) steel sledgehammer, and any others you find useful

Pullers and presses: Pitman arm puller, all models and sizes, but definitely keep 2 and 3-arm and steering-wheel types on hand - Picks: Heavy-duty as well as smaller, dental-type picks

Wire wheels and brushes: Cheap, disposable brushes can be used for initial cleanings, but also invest in specialty brushes to finish up - Impact gun (battery-powered): Also consider corded ones for those times when you can’t use a compressor

Scan tool: Something like the Power Probe III is user-friendly and will help you check electrical components and locate short circuits - Specialty tools: Disconnects, spindle-nut sockets, tubing wrenches

Purchasing Your Tools

Between equipping yourself for school and adding on recommended tools, it’s easy to become overwhelmed—and drain your bank account in the process.

Fortunately, experts have advice on affordable ways to get ahold of the tools you need. You can search online to buy used sets. Keep an eye out for school sales, too. Programs like the one you got your certification from sell their used tools on a regular basis when they upgrade their equipment. Lowes, Harbor Freight, and Sears also typically offer reasonable prices on heavy-duty tools.

Additionally, you could consider opening an account with a company that specializes in the type of tools you need, such as Snap-On, MACO, or Mac.

Do I Need Expensive Gear?

Your toolbox is going to be an expensive investment over the years no matter what you do—so keep pricing in mind while looking at potential additions.

It makes sense to spend a little more on truck tools you frequently use because you’ll need them to last for the long haul. On the other hand, buy cheap when you’re shopping for semi truck tools that you rarely need. For example, adjustable wrenches, pry bars, and long screwdrivers are tools you don’t have to spend a fortune on.

Warranties Save Money

Here’s a tip we wish someone had shared with us way back when: If you can buy heavy-duty tools with a warranty, do it. Since you’re building a business along with your toolbox, it makes financial sense to invest in the must-have truck tools that manufacturers guarantee. Those with lifetime warranties are the most valuable because you will only have to spend money on them once. If they ever break, replacing them won’t cost a cent.

Growing as a Diesel Mechanic

Heavy-duty tools can be expensive, so the best way to build the ultimate truck toolkit is to do it over time. First, buy specialty tools as you need them, but consider buying used when it comes to big-ticket items. You can also make a “wish list” of tools you’d like but don’t need right away—you can pick these up during sales or special occasions (or, y’know, someone can get one for you during National Diesel Tech Appreciation Week).

Additionally, upgrade as you go. Replace older tools as they wear out. You’ll have more to invest in better-quality ones as time passes and you’re making more money.

Essential Tool List

If money and space weren’t issues, what would the essential heavy-duty toolbox look like? You’d have a dream collection of socket sets, wrenches, pliers, and files, to be sure. To get very specific, the essential tool list would probably look something like this:

- 1/4-inch drive socket set

- 3/16” – 1/2” standard depth

- 3/16” – 1/2” deep

- 4mm – 13mm standard depth

- 4mm – 13mm deep

- Extensions short, medium, long

- Ratchet handle

- Universal joint

- 3/8-inch drive socket set

- 3/8” – 3/4” standard depth 1/2 point

- 3/8” – 3/4” deep 6 point

- 10mm – 19mm standard depth

- 10mm – 19mm deep

- Extensions short, medium, long ratchet handle

- Universal joint

- 3/8” – 3/4” square drive flexible socket torque wrench 0-250 in-lb.

- 1/2-inch drive socket set

- 1/2” – 1 1/8” shallow

- 1/2” – 1 1/8” deep

- 13mm – 32mm shallow

- 13mm – 32mm deep

- Square drive stud remover tool

- Breaker bar

- Extensions short, medium, long

- Ratchet handle

- Universal joint

- Torque wrench 0-250 ft-lb.

- Wrenches

- Combination: standard 3/8” to 1 1/4” metric 6mm to 26mm

- Flare nut: standard 3/8” to 1 1/4” metric 6mm to 26mm

- Adjustable: 8” and 12”

- Allen sets: standard .050” to 3/8”, metric 2mm to 12mm

- Torx set: t-15 to t-55

- Pipe wrench: 10” or 14”

- Reversing chain wrench: 20”

- Screwdrivers

- 1”, 6”, 9”, 12”, and offset blade types

- Phillips: 1” #2, 6” #1 and #2, 12” #3

- Hammers

- 16 and 24-ounce ball peen and 2 1/2-pound heavy duty plastic

- Punches

- Pin 3/16” to 3/8”

- Center 5”

- Cold chisel

- Starter 3/16” to 3/8”

- Brass punch

- Feeler gauges

Don’t Forget This Heavy-Duty Tool

You know what other tool every diesel repair shop can benefit from? A solid shop management software to help the business run smoothly. Fullbay offers a variety of features that automate ordinary tasks and increase efficiency. It can track PMs, monitor your inventory, create estimates and invoices, assign and monitor jobs, manage parts and orders, and even help you communicate with customers. It’s an essential tool for any heavy-duty shop.

Want to add this tool to your toolbox? Give our free demo a try today!